NFPA 70E provides guidelines for the protection of workers during the event of electrical hazards such as arc flashes. The standard outlines clear actions to take in the event of electrical occurrences as well as steps to take to mitigate potential risks.

One of the key aspects the standard covers is the importance of arc rated FR workwear that protects wearers in the event of electrical dangers.

What causes arc flashes and why do they pose such a high risk?

Arc flashes occur when electric currents leave their intended paths and travel through the air to the closest conductor. When working in an electrical environment, the closest conductor is most often the worker.

Arc flashes can be caused by many incidents or changes in the working environment. A few key causes include:

- The presence of combustible dust offers an airborne path for currents to move through.

- Tools that are dropped during work can cause a disturbance in the flow of the current.

- Condensation or moisture rich environments where currents are offered an alternative path to travel.

- Corrosion, insulation material failure, and faulty installations that allow currents to escape.

The results of an arc flash include burns, fire, and intense heat, all factors that can be protected against with the right FR clothing.

NFPA 70E guidelines for arc rated PPE

Electrical hazards vary greatly in risk levels according to the specific environment. As such, the NFPA 70E standard provides detailed guidelines for four categories of protective wear.

Each category includes an outline of the protective gear needed to offer efficient protection to workers in low (category 1) to high (category 4) risk environments.

These guidelines cover everything from undergarments to protective gear such as goggles and hard hats. Categories 3 and 4 also require specific arc related protective gear, such as arc flash suits and hoods.

The most important consideration in FR PPE garment selection is each category’s arc rating requirements:

- Category 1: 5 calories per square centimeter

- Category 2: 8 calories per square centimeter

- Category 3: 25 calories per square centimeter

- Category 4: 40 calories per square centimeter

These arc ratings help you select the FR fabric that offers optimal protection for the hazards that your workforce may encounter.

How are FR fabrics tested for NFPA 70E compliance?

To ensure optimal safety under hazardous workplace conditions, the following NFPA 70E tests are administered on the fabrics used to produce FR garments.

- ASTM D7138 - Thread Melting Resistance

To ensure the flame resistance of the fiber, the thread used in the garment may not melt when exposed to thermal conditions of up to 500F.

- ASTM D6413 - Vertical Flame Resistance

The fabric used in the garment is exposed to a vertical flame for 12 seconds, and should meet the following requirements after 25 washing cycles:- It must self extinguish in 2 seconds or less after the flame is removed

- The fabrics must exhibit a char length of fewer than 6 inches

- Once the flame is extinguished, the fabric may not melt or drip

- ASTM F1959 - Arc Testing

The final test determines the level of heat the fabric blocks from an electric arc to mitigate the risk of second-degree burns for the wearer.

These tests are usually administered on the fabric itself, and not the garment as a whole. But manufacturers can choose to perform testing on final garments to ensure increased protection.

Industries that require arc-rated FR garments

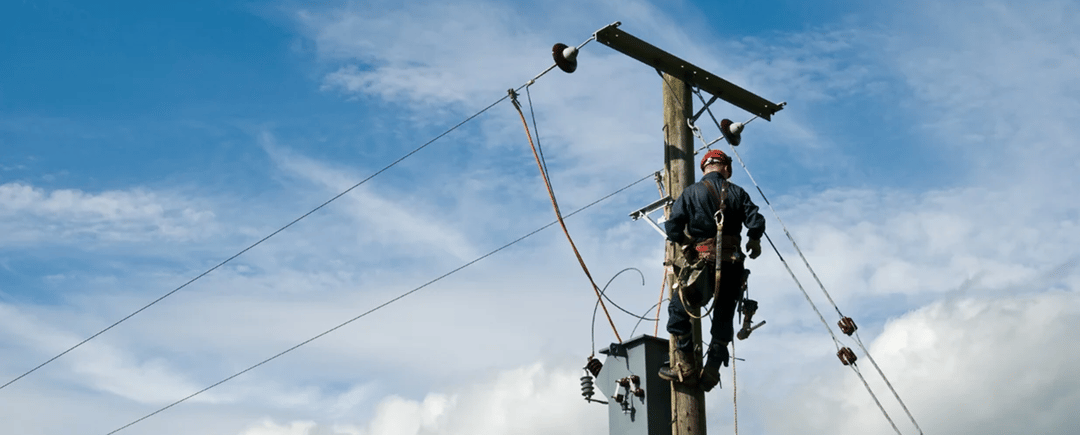

Compliance with NFPA 70E is mandatory for all industries and professions where electrical construction and maintenance work takes place.

Examples of fields where NFPA 70E compliant PPE gear is required are:

- Construction sites

- Industrial plants

- Contractors

- Electrical engineers and inspectors

- HVAC installers

For these workers and in these industries, safety and moveability are equally important. The physical labor involved in these industries requires PPE clothing that does not get in the way of productivity.

Choosing the best suited, arc rated FR protection for your workforce

Inherent FR fabrics ensure increased durability and protection that will last while not sacrificing comfort. These fabrics don’t restrict the wearer’s movement, limiting the risk of flash fires caused by human error.

When choosing the best arc rated FR garments for your workforce, NFPA 70E offers you valuable guidelines to ensure the wearer’s safety. Speak to a TenCate Protective Fabrics expert today and learn about the fabrics best suited for your work environment.

.png?width=399&name=Untitled%20design%20(33).png)