Each year, the Occupational Safety and Health Administration (OSHA) issues its report on the top violations as measured by number of citations within the fiscal year. For 2022, these were the top ten cited standards:

- Fall Protection – General Requirements (Standard 1926.501)

- Hazard Communication (Standard 1910.1200)

- Ladders (Standard 1926.1053)

- Respiratory Protection (Standard 1910.134)

- Scaffolding (Standard 1926.451)

- Lockout/Tagout (Standard 1910.147)

- Powered Industrial Trucks (Standard 1910.178)

- Fall Protection – Training Requirements (Standard 1926.503)

- Personal Protective and Lifesaving Equipment – Eye and Face Protection (Standard 1926.102)

- Machine Guarding (Standard 1910.212)

All these top hits are repeat offenders, with Fall Protection – General Requirements ranking as the number one most frequently cited standard for twelve years in a row. These standards highlight opportunities for employers in every industry to bolster their safety strategies especially in these areas to reduce violation incidences.

When a Citation Occurs

OSHA usually only comes to your worksite when a report has been made that warrants their investigation, such as an injury, fatality, or worker complaint. When they visit you, it’s for a reason; there has most likely been a violation of one of these standards that will quickly present itself to an investigator. For example, if an employee fell off a roof and there was no barrier 6’ from the edge of the roof, or they weren’t wearing a harness, it’s going to be immediately apparent to the OSHA investigator that the Fall Protection standards weren’t being followed.

OSHA will typically focus on the incident at hand, but they could also review your overall safety programs and policies to ensure that they are in compliance with regulations. After OSHA issues a citation, there is often an associated fine assessed to the employer, and they will ask for proof that the violation has been corrected.

Mitigating Specific Violation Risks

There are specific items and policies an OSHA investigator will look at to assess compliance with each of these standards. These are some examples of what they consider and how you could wind up with a citation if you’re missing a crucial piece of your risk mitigation strategy:

- Fall protection:

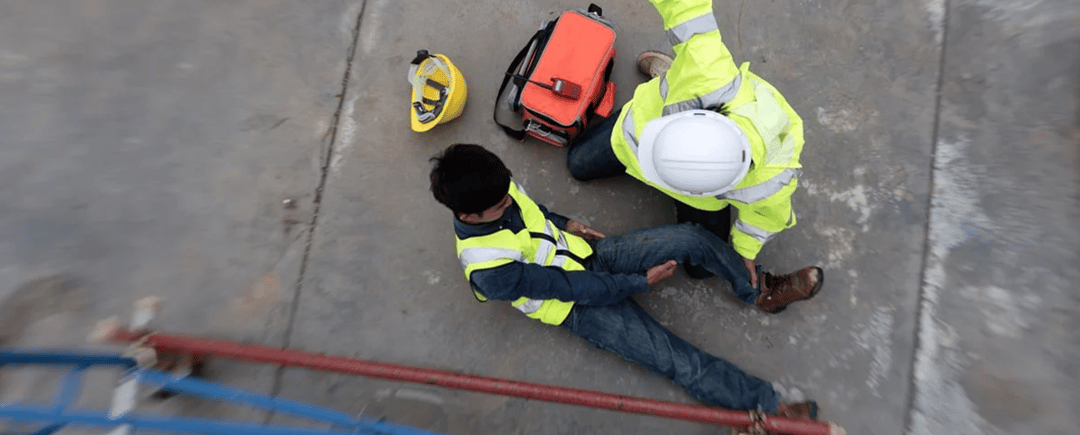

While not all top OSHA violations correspond to top injuries, Fall Protection usually does, with slip and fall injuries topping the list. When OSHA comes in to investigate a fall, it’s typically when an employee has fallen from a height to a lower level. They’ll look at your fall protection program, including the training you provide your employees, and whether they have the proper protection provided for working above the ground, such as roof barriers and harnesses. If a piece of the fall protection program puzzle is missing, you’ll likely see a citation. - Hazard Communication:

Hazard Communication relates to chemical safety; your employees need access to information about the chemicals they’re using, as well as proper PPE and precautions protocols. OSHA will ask employees if they have access to Safety Data Sheets for every chemical, and if they have training for how to read chemical labels. If Safety Data Sheets are not readily available, or you lack a written HazCom program, OSHA will issue a citation. - Ladders:

Incorrect usage of ladders or a lack of a written program for inspecting ladders can result in some pretty big citations from OSHA: if they are investigating an employee fall from a ladder and the ladder in question is missing two steps, you’re going to have a problem. You need to ensure that employees understand what type of ladder to use when. A-frame ladders are often marketed as appropriate for general purposes, but not everyone knows you need to always maintain three points of contact on an A-frame ladder. If an employee is using an A-frame for a task that requires both hands to come off the ladder, they’re not using the right kind of ladder and need to be on a platform ladder with a stable surface. - Respiratory Protection:

For employees working with volatile materials that produce fumes, or performs activities such as welding, they must have proper respirators for their work. Not only must they be the correct type of respirators for the work, but they must be fit tested for the employees and properly maintained and cleaned. You need a written program outlining how respirators are selected, provided, and maintained and your respirators in good shape in order to comply with this standard. - Scaffolding:

When an employee falls from scaffolding, OSHA will look at the area where they fell from and check for the scaffold tag, weak points, and general scaffold construction, as well as inspection records. If the scaffolding hasn’t been inspected, doesn’t have tags, or isn’t erected the way it should be, that will result in a violation citation. - Lockout/Tagout:

Lockout/Tagout is an extremely important standard that protects employees who work in and around equipment with moving machinery parts or electrical components. If a worker is inside and a piece of equipment is accidentally turned on, they can suffer serious injury or death. Equipment must be shut off, sometimes at multiple points, and then locked in the off position. Any employees who are authorized to perform a lockout/tagout must be properly trained to do so; if there’s no training record for an authorized employee, that will stand out immediately to OSHA.

Safety Has No End Game

Preventing violations of OSHA standards in your workplace begins with cultivating an organizational safety culture with a growth mindset. We’re only fifty odd years into protecting employee safety in the U.S. as governed by the Occupational Safety and Health Act of 1970; safety professionals and stakeholders are continuously improving programs and policies to keep their workers safer on the job.

The moment a company dusts off their hands saying, “Well, we did it! Everything is in place to ensure safety, there’s nothing more to do!” they have become complacent and will quickly fall behind the ever evolving safety standards across industries. There is no end game to safety, and improvement relies on participation and engagement with everyone involved, from the C-suite to the field and the floor.

Strong Safety Cultures Communicate

Reducing the incidences of preventable injuries and fatalities on the job requires a multi layered approach with channels for communication kept wide open. Of course, regular classroom setting safety trainings are important, but when workers are at work, everyone must be committed to safety, from employees to safety committees to supervisors to superintendents to plant managers and beyond.

A safety observation program can give employees the ability to recognize both safe and unsafe behaviors and communicate with each other and management personnel to reinforce positive safety behaviors and have productive conversations around unsafe behaviors. Tracking these behaviors through a logging system can help safety managers and their teams identify trends, hazards, and topics to develop further training around.

Safety managers are responsible for driving risk reduction, but they don’t have to, nor should they, be the only person looking out for and mitigating hazards. If two heads are better than one, 500 heads are phenomenal when they are all equally invested in improving workplace safety and taking responsibility for keeping themselves and others safe. Safety managers may have a small team when it comes to job titles, but when they encourage awareness, engagement, and commitment throughout the organization, they can have a team of hundreds. And when a team of hundreds works together to improve and maintain safe practices, the potential for OSHA citations plummets.

Learn more about how to cultivate strong safety cultures here, or reach out to a TenCate Protective Fabrics expert to discuss your safety strategy.

.jpg)

.png?width=399&name=Untitled%20design%20(40).png)